EPB-type TBMs are particularly used in soft or medium/soft soils with a high clay or silt clay content, which have low water penetration. The working areas inside the machine are completely sealed against the outside ground pressure.

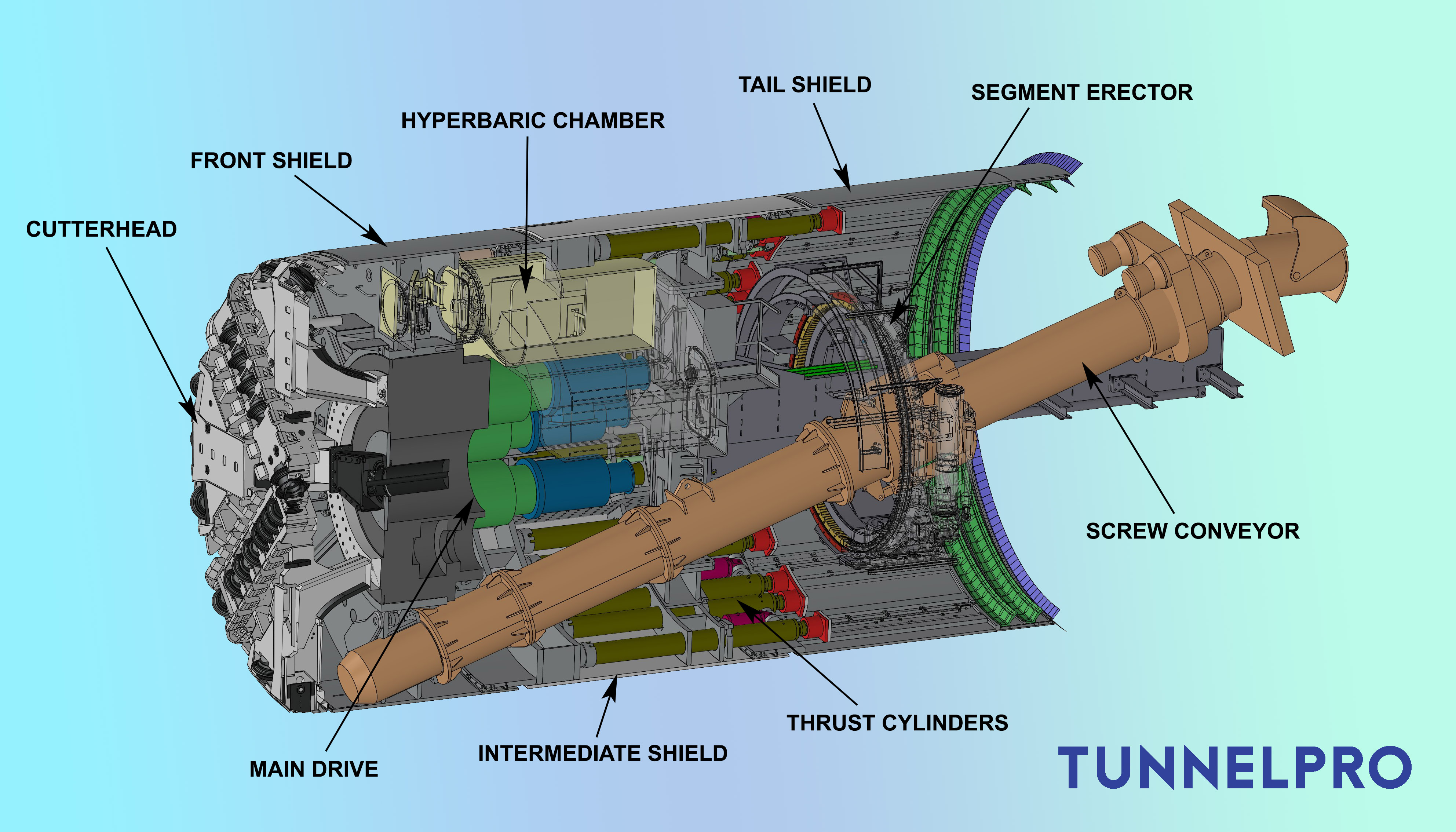

The medium through which the excavation front is supported during the advancement of an EPB is represented by the excavated material itself. Even in case of water inflows, the material inside the excavation chamber must be kept highly viscous, e.g. through the introduction of special additives (ground conditioning foams) that create a fluid as homogeneous and consistent as possible, in order to allow the transfer of pressure and facilitate the extraction of material from the excavation chamber which is achieved through a screw conveyor.

The pressure inside the excavation chamber must always be kept under control, to avoid settlements or repercussions on the surface above the tunnel, so it’s constantly recorded by load cells. During the boring phase the pressure is controlled by regulating the advancing rate and the screw conveyor’s rotation speed, and other types of systems can cope with sudden pressure losses even when the TBM is not excavating.